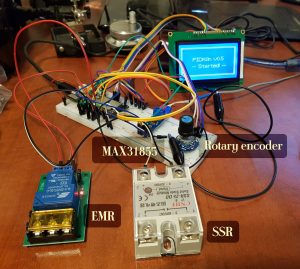

PIDKiln v1.2 update

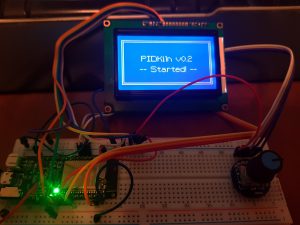

I’ve just created v1.1 release of PIDKiln, and bumped development version to v1.2.

Most significant change in release 1.1 are:

- replaced MAX31855 library with another one – it’s much cleaner and easier to modify

- much better MAX31855 error handling, both with thermocouple and MAX31855 itself

- introduced network logging with syslog protocol – so you can watch all debug information on remote host

- all logging settings are now in Preferences

- compressed local JS, and created separate Preference setting to allow remote downloading of JS scripts (Internet connection required – recommended to use)

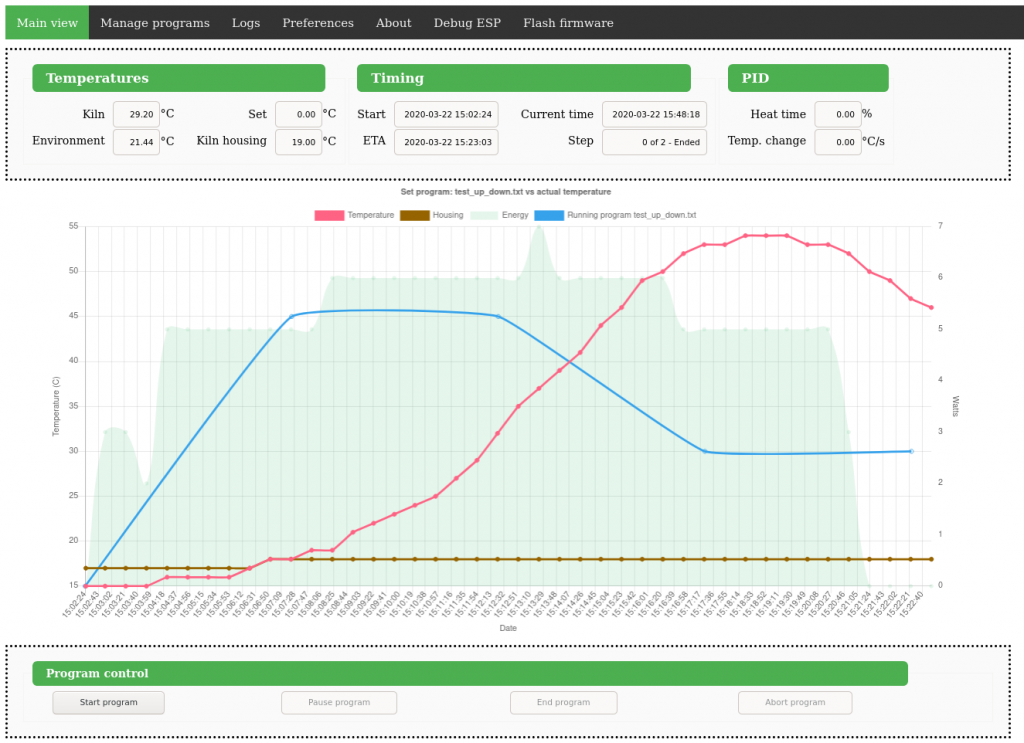

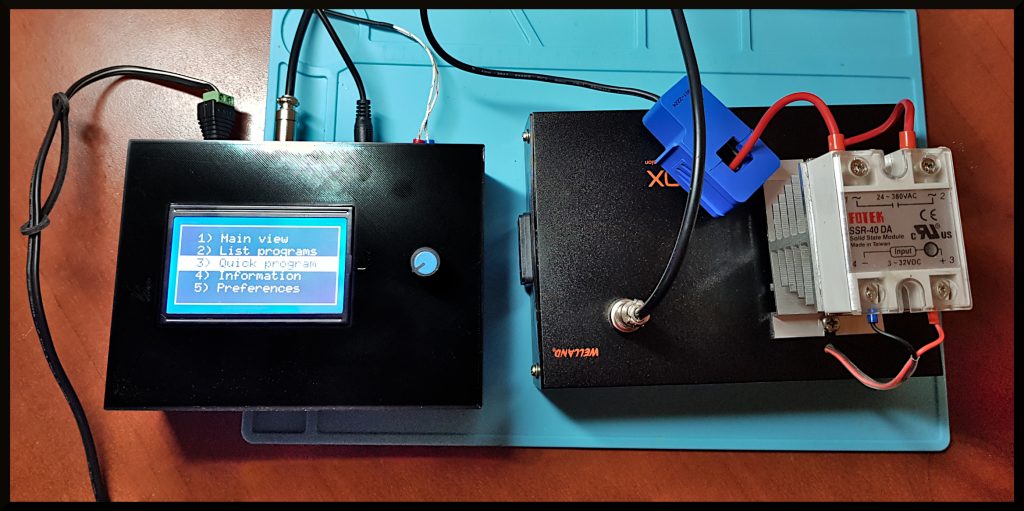

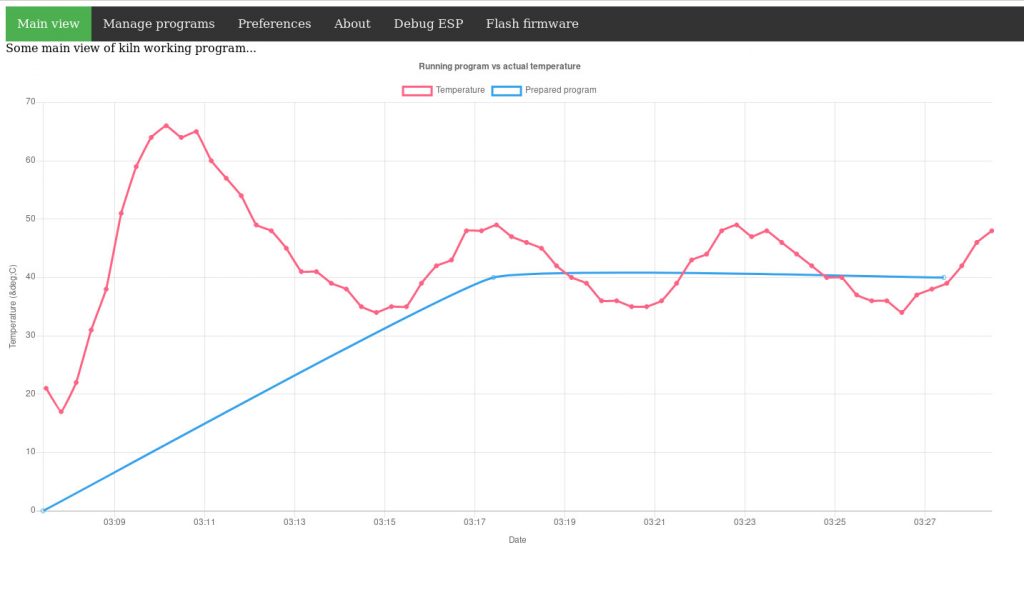

And I have also (after some 1.2 changes) first, real Kiln test run.

With two termocouples and power meters.

Source like always on GitHub.

Recent comments